Description of nozzle:

A nozzle is a device designed to control the direction or characteristics of a fluid flow (especially to increase velocity) as it exits (or enters) an enclosed chamber or pipe.

A nozzle is often a pipe or tube of varying cross sectional area, and it can be used to direct or modify the flow of a fluid . Nozzles are frequently used to control the rate of flow, speed, direction, mass, shape, and the pressure of the stream that emerges from them. In a nozzle, the velocity of fluid increases at the expense of its pressure energy.

Material of construction:

The material of construction is selected based on the fluid properties of the liquid that is to be filled and the environment surrounding the nozzle. These nozzles are most commonly fabricated from metals, What is the appropriate use of each material in making nozzles? such as brass, Stainless steel, and nickel alloys, but plastics such as PTFE and PVC and ceramics (alumina and silicon carbide) are also used . Several factors must be considered, including erosive wear, chemical attack, and the effects of high temperature.

The appropriate use of each material in making nozzles:

- Brass – The most common metal used for nozzles, brass can be used to print PLA, ABS, PETG, Nylon, TPE, TPU, PC, and most any other non-abrasive materials.

- Stainless steel – Stainless steel is ideal if you need a lead-free nozzle for FDA-approved materials or medical devices.

- Hardened steel – If you want to print abrasive materials, like ColorFabb bronzeFill for example, hardened steel nozzles are what you want.

- Specialty materials – Other materials, like Tungsten and Ruby, have been used to make harder nozzles that can stand up to constant abrasion. These are for printing exclusively abrasive materials, and typically cost more than the other options.

Nozzle Diameter:

The diameter of the nozzle is, perhaps, the most important factor when choosing a nozzle. This is because of how much it affects the resolution of filling machines . The size directly affects the amount of production , The nozzle hole should be proportional to the hole of bottle we fill,Using a simple ball valve to open and close nozzles also allows the fill heads to make use of any number of different nozzle tips. These tips may be stainless steel or plastic, round or flat. The product, package and production rate will help to identify the perfect fill head and nozzle tip for your given project.

Nozzle wear

Nozzle wear is indicated by an increase in nozzle capacity and by a change in the core pattern, in which the uniformity of filling pattern deteriorates and increases and changes drop size and the amount of pouring . Choice of a wear-resistant material of construction increases nozzle life . Because many single fluid nozzles are used to meter flows, worn nozzles result in excessive liquid usage.

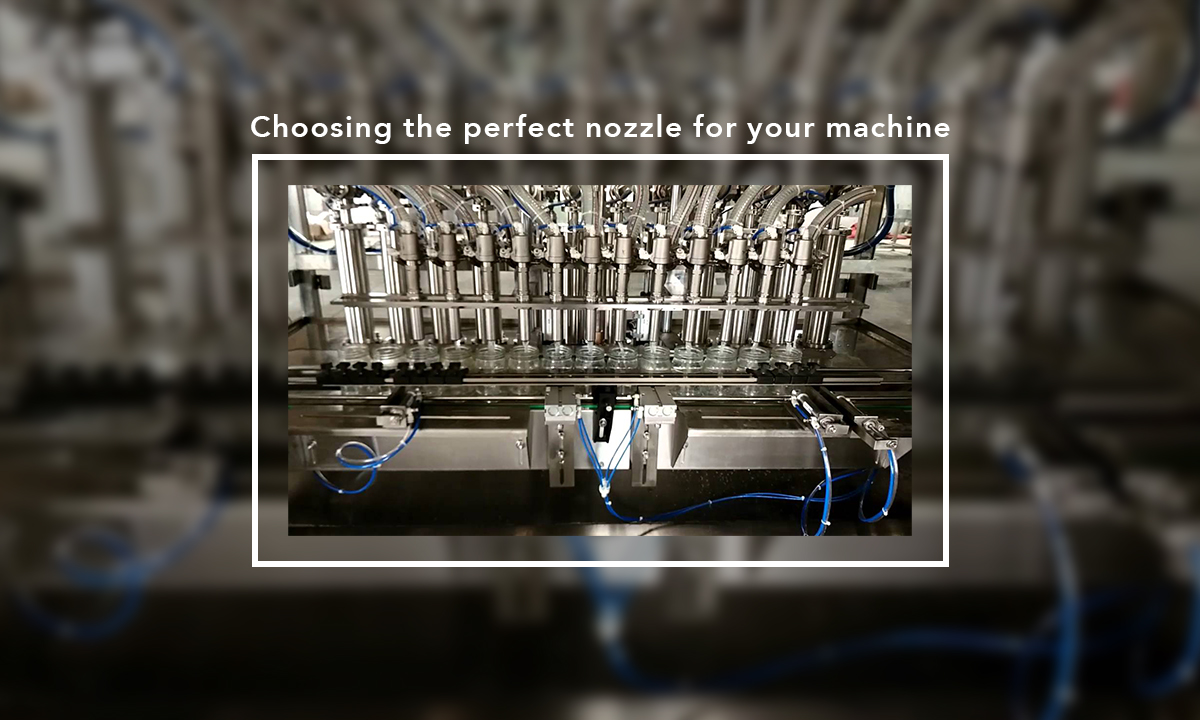

How to choose perfect nozzle for you machine

.The filler nozzle type used will depend on product factors such as viscosity, tendency to form caverns, existence of particulates, temperature and much more. The best way to determine the ideal solution for filler type and fill nozzles is to discuss the same with your machinery manufacturer.

Types of nozzles:

-

Jet.

-

High velocity.

-

Propelling.

-

Magnetic.

-

Spray.

-

Vacuum.

-

Shaping.

Piston_pump_machine_CUBII

Piston_pump_machine_CUBII

Cubii Engineering Company is distinguished by producing distinguished machines, including a high-density liquid filling machine, which is one of the best machines of this type in the market, so if you are interested in knowing any other details, you can follow this video: