Pickled foods

Without a doubt, pickles are as old as vinegar and spices. Cucumber has been grown more than 3,000 years ago. Sauerkraut fermented cabbage can be traced back to ancient China. The Egyptians used vinegar in their cooking and their knowledge of the fermentation process, to the conclusion that pickling also originated before history was written, and even in the days of the Romans, pickle factories were found in Spain. They preserved the meat in brine, followed by soaking in milk to remove most of the salt.

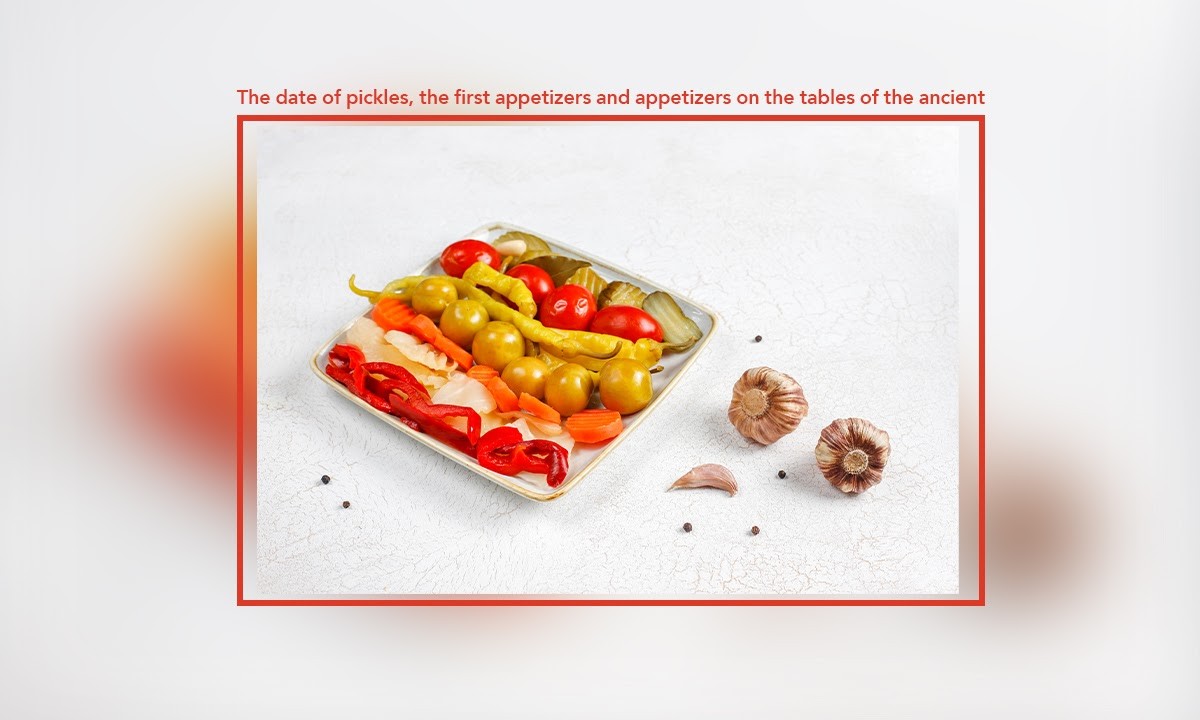

There are many types of fruits and vegetables that can be preserved by pickling, and the package may contain one type or a mixture of several types. When chopped or roughly grated, they are used as Relish dressings or Chutney salads, and when finely chopped they are added to sauces, spreads, or dressings. In each section there are numerous variations and overlaps of sizes, cuts, methods of analysis and final composition. For example, cucumber pickles range in size from very small to large, or they may be packed in the form of longitudinal quarters or transverse rings. They may be worked and prepared into cubes or heralded as Relish. Sugar, vinegar, dill, or mustard may be added. Similar varieties can be in both the fruit or the vegetable used, although the fruit is often sweet and spicy.

(1) Cucumber pickles and relishes

Pickled varieties should have firm flesh and cut when under ripe. The fruits should not be scratched, and a short portion of the stem should be left attached to it upon picking (collection). After initial scaling, they are treated with 10% brine, where they ferment. This process lasts 4-6 weeks. The salt concentration should be maintained and re-adjusted whenever needed throughout the salting period. Sometimes 1% dextrose is added to control the fermentation process, preventing air as much as possible to allow lactic acid bacteria to multiply. In the first steps, carbon dioxide is produced and must be let out. When salting is done, the pickles will be yellow or olive in color. It is then stored in a more concentrated brine until ready for final processing. The final processing consists of carefully scaling the size, soaking in water to remove the salt, and then adding vinegar. The soaking process takes several days in separate basins. Calcium chloride or Alum is added to harden the texture. Turmeric is used to improve the color, then the process of adding vinegar is done by soaking the pickle in a basin or more of vinegar with the desired strength, to give a final concentration of 2.5-3.5% acetic acid. And if filled at these steps, the pickles are sour pickles and sweet pickles. They differ in that the last soaking in vinegar uses spiced sweet vinegar.

(2) Dill pickles

Dill pickles can be divided into fresh pasteurized or real dill pickle. It consists of larger pickles that are fermented in drums of 40-50 gallons (151.4-189.27 liters) with sheet grass, sheet vinegar and dill spices.

Dill herb is placed at the bottom of clean drums and half filled with cucumber and spice mixture, then salt is added, and after shaking, more sheet spices, salt and vinegar are added to the surface, then the barrels are filled with water or brine. The drums are placed on their sides with the nozzles closed, where the fermentation takes its course and the best temperature for fermentation is 26.6-29.4 ° C, the period is 6-8 weeks.

To obtain the shelf life of kava, it is usually pasteurized by pickling by placing the pickle in jars and covered with brine from the main fermentation solution. Turbidity is removed from the brine by filtration. The brine is heated to 71.1-76.6 m and poured on the crowbar. After the cap is closed, it is pasteurized at 73.5 ° C for 15 minutes, followed by immediate cooling.

Most of the pickles are packaged in glass jars, and if you use tin cans, they should be heavy mince and varnish

Packaging

Pickles can be packed in tin cans mixed with heavy varnish if the cans are heated to 93.3 m for 15 minutes before sealing. A further sterilization of 93.3 m for a period of 10 minutes is required, as a precaution. Most of the pickles are packed in glass jars and sealed tightly, and it is detailed to use vacuum. We reach the discharge by pushing steam into the upper space just before locking. Usually saline solutions are filtered to remove turbidity or replaced with fresh solutions. The sizes of the used jars are 6 (177.4 mil), 10 (295.7ml), 16 (473.2ml), 20 oz (21ml). The large half gallon (1.9 liter), gallon (3.78 liter) sizes are usually used for restaurants and establishments. Metal caps are used with cork or cardboard liners with the use of a welding compound that fuses heat around the lip.

Plastic bottles are used in addition to bags to fill pickle products, and since the dill pickle spoils quickly unless it is pasteurized, these last packages have a short shelf life. Another problem with using plastic for pickles is the possibility of diffusion of acetic acid through the walls of the package. If the pickles are not pasteurized, they depend on acetic acid for their bacteriological stability. Loss of acetic acid through the walls of the package can shorten the shelf life and cause contamination. Other materials used for pickle bags include polyamide-polyethylene bags.

One of the recent trends in the process of packing pickles in general is the use of polyethylene bags covered with polyethylene in printed paper cartons.

The development of flexible packaging for sterilization has caused remarkable progress in flexible packaging for pickles, whether in bags of light-permeable films or made from sheets of aluminum foil. There is also another trend, which is the use of the Pure Pack cartons used in yogurt to fill slices of dill pickles.

To view the line of world-class pickle plate welding machine from cubii, click on the following link

http://https://www.youtube.com/watch?v=3-h7iJlOhLU