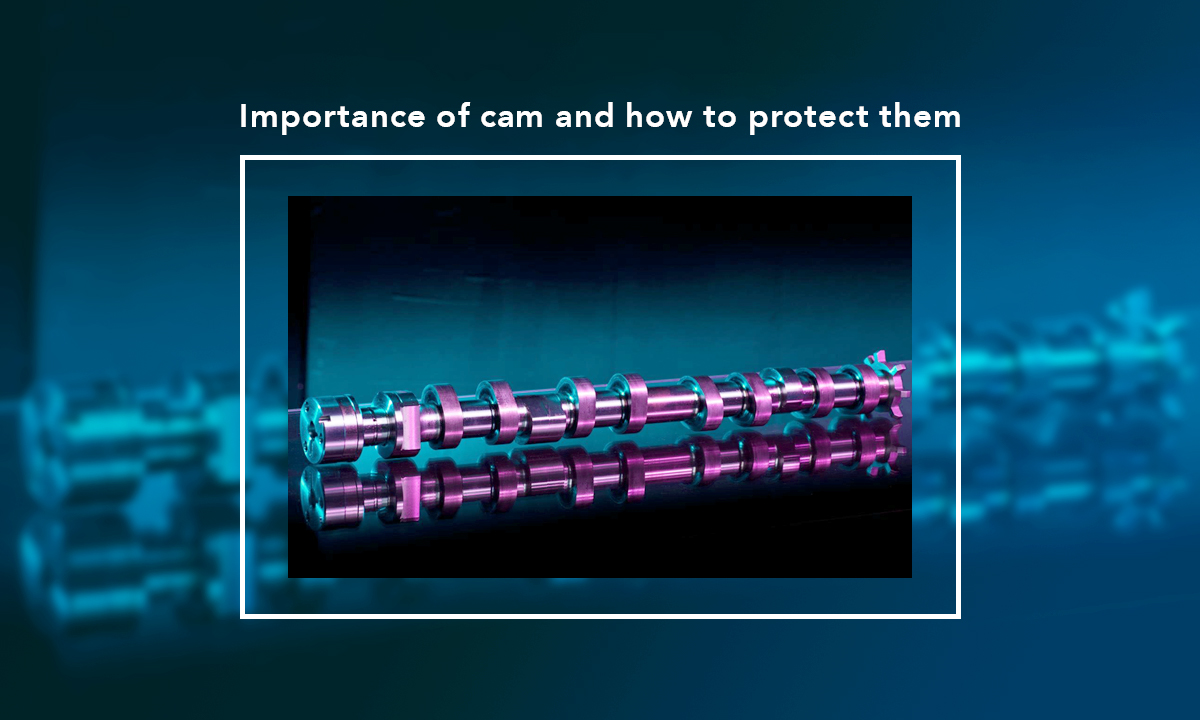

The CAMshaft is a complex piece of some machinery. There are hundreds of moving parts that all have to work together in a coordinated effort in order to function correctly in the machine. One of the key components to managing this effort is the camshaft . Sometimes called a “bump stock” or “cam”, the cam also runs the mechanical high-pressure fuel pump, so suffice it to say, the cam is critical to the engine’s operation.

Over time, the camshaft can wear down or become damaged, requiring replacement. For high-performance applications,The process of creating this critical component is quite unique, so we ,to see what are the different ways of manufacturing this important piece (camshaft) .

CAM: A projection on a rotating part in machinery, designed to make sliding contact with another part while rotating and to impart reciprocal or variable motion to it. Cams are used to convert rotary motion into reciprocating motion

CAMSHAFT: a shaft with one or more cams attached to it, e.g. working of valves in an internal combustion engine is controlled by camshaft. Camshaft is called the “brain” of the engine.

History of camshaft:The camshaft was described in 1206 by syrian engineer (Al-Jazari ). He employed it as part of his automata, water-raising machines, and water clocks such as the castle clock.

Among the first cars to utilize engines with single overhead camshafts were the Maudslay designed by Alexander Craig and introduced in 1902 and the Marr Auto Car designed by Michigan native Walter Lorenzo Marr in 1903.

Material of cams:

Camshafts can be made out of several different types of material. These include Chilled iron castings: this is a good choice for high volume production. A chilled iron camshaft has resistance against wear because the camshaft lobes have been chilled, generally making them harder. When making chilled iron castings, other elements are added to the iron before casting to make the material more suitable for its application.

Billet Steel: When a high-quality camshaft is required, engine builders and camshaft manufacturers choose to make the camshaft from steel billet. This method is also used for low volume production. This is a much more time-consuming process and is generally more expensive than other methods. However, the finished product is far superior. When making the camshaft, CNC lathes, CNC milling machines, and CNC camshaft grinders will be used.

Conclusion of choosing best material for camshafts:

When purchasing a camshaft, enquire which material the camshafts are produced from.A chilled iron camshaft may be more expensive, but its resistance to wear in all conditions, far exceeds any other type of cast iron.

CAM shape:

-

- PLATE CAM OR DISC CAM:The follower moves in a plane perpendicular to the axis of rotation of the camshaft. A translating or a swing arm follower must be constrained to maintain contact with the cam profile.

- GROOVED CAM Or closed cam:This is a plate cam with

-

- the follower riding in a groove in the face of the cam.

- CYLINDRICAL CAM OR BARREL CAM:The roller follower operates in a groove cut on the periphery of a cylinder. The follower may translate or oscillate. If the cylindrical surface is replaced by a conical one, a conical cam results

- END CAM:This cam has a rotating portion of a cylinder.The follower translates or oscillates, whereas the cam usually rotates. The end cam is rarely used because of the cost and the difficulty in cutting its contour.

METHODS OF MANUFACTURING cams:

- CASTING

- FORGING

- MACHINING

After manufacturing process, inspection is the most important step:

Measuring Machine used to check for Tolerances -Runouts and Diameters of journals ( all 6 and center 4). The machine then declares the component as OK, NG, or BAD.

Automatic_Filling_And_Sealing_Machine_CUBII

This video is an introductory video about the CUBII machine for filling and sealing containers, and it is one of the machines with high efficiency, speed and smoothness